Ändra språk :

smart plastics new products

Our new products from

News 2024

The growing importance of smart condition monitoring and predictive maintenance

The integration of IIoT into industrial processes simplifies condition monitoring and predictive maintenance. With our new products, we are moving further in the direction of Industry 4.0. Sensor-based information enables us to make precise statements about the expected service life of products. Downtimes can be reduced and production efficiency increased. We are constantly developing our products to enable precise maintenance planning and provide accurate information on the condition of the system at all times.

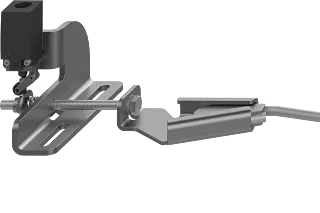

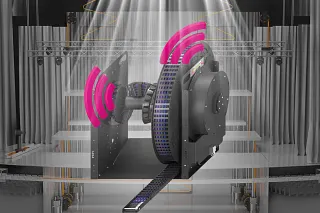

EC.IT Contactless status sensor ...

... for roller energy chains with direct superwise connection

The non-contact EC.IT sensor collects data during operation virtually "in flight". Thanks to the direct connection to the superwise service, the EC.IT sensor box can display valuable information on service life, provide maintenance instructions and draw attention to any irregularities. In addition, all relevant information can be viewed in a compact and clearly structured form on the dashboard.

The OTA-capable i.Sense module ...

... with connection to the superwise service

The i.Sense GEN II NEW module now with over-the-air (OTA) updates for firmware and operating software, records motion profile data from your machines and enables an IoT connection to the superwise portal in addition to the tried-and-tested tension, thrust and breakage monitoring. Reliably prevents system failures caused by foreign objects, misalignment or weather influences.

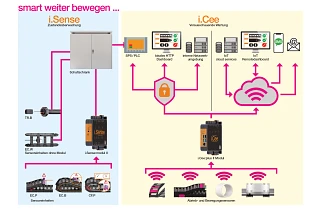

i.Cee integrated superwise maintenance management

Plan service calls and retrofits intelligently. With the addition of a new maintenance management module to the firmware and the connection to the superwise system, a smart step can be taken in service management. The module enables optimised maintenance planning. Systems can be serviced more efficiently and unplanned downtimes can be reduced. By integrating the maintenance management module into the superwise system, a smart step can be taken towards improving maintenance processes.

The ComBox for all i.Sense modules

All sensors in one box ... seamlessly integrated into the superwise system

With the ComBox, real-time information is seamlessly integrated into the superwise system. This compact solution combines all i.Sense sensors in a single device and offers optimal integration into the superwise service for condition monitoring. The clear dashboard not only displays service life information and maintenance instructions, but also alarms in the event of anomalies to ensure efficient and proactive maintenance.

Quickly detect power failures with the CF-D module ...

... now with event log and Profinet Ethercat capability

The CF-D module can quickly detect cable failures and is therefore crucial for effective and accurate maintenance of Ethernet cables. With the new event log function and compatibility with Profinet Ethercat, the i.Sense CF.D module takes fault diagnostics to a new level: It precisely pinpoints the location of transmission faults, allowing maintenance work to be carried out quickly and accurately.

Recognise the condition of the chain at a glance ...

... with the condition indicator

The mechanical condition indicator with coloured indicators (green, yellow, red). This is revealed by the abrasion of the wear additives of the chain links. The colour changes to yellow with increasing abrasion. The decreasing distance between the crossbars indicates the state of wear.

Smart igubal® flange mounted bearing ...

... equipped with an abrasion sensor

The igubal® flange mounted bearings are equipped with an abrasion sensor that is integrated into the polymer spherical ball. Conductive elements are interrupted by the wear. The resulting percentage condition values are transmitted either to the local i.Cee system or to the superwise cloud solution via a long range network (LoRa).

The new distance measuring system ...

... with a measuring accuracy of up to 1mm

Precise positioning is no longer a problem. With the new displacement measuring system, positions can be determined with an accuracy of 1mm.

Ball coupling without lubrication

With the intelligent trailer coupling, maintenance can be planned safely. A sensor measures the wear on the bearing and informs you in good time when a bearing needs to be replaced. Failures and damage can lead to high costs in the agricultural sector. This can be prevented with the smart spherical ball.

Our new products from

News 2023

Moving energy made smart

Do you know how expensive one hour of plant downtime is for industrial companies? Please note: between 39,000 and 2 million US dollars, according to a study by Senseye, a manufacturer of analytics software from the UK. Costs that add up. The 500 companies with the highest turnover in the world lose virtually 1.5 trillion US dollars per year due to system failures. An insane burden on profits that can no longer be ignored. Not even in small and medium-sized companies. It is therefore not surprising that more and more companies are looking into future-oriented topics such as condition monitoring and predictive maintenance. This is an important step towards minimising downtimes and making maintenance work more economical.

smart plastics meets orange service

superwise - igus® smart service

For the first time, the innovative superwise service combines the first-class igus® orange product service with state-of-the-art smart plastics technology in a single package. Thanks to the systematic and AI-supported evaluation of the customer's application and project data, igus® with superwise offers a whole host of benefits. For example, we can actively inform the customer about price, delivery time and possible product improvements before an upcoming replacement.

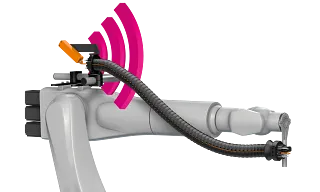

Flexibility meets safety: i.Sense TR.B

First monitoring system for e-chain® robots

Robots have long been an integral part of many areas of industrial production - welding, painting, soldering or palletising: industrial robots work dynamically. A flexible multi-axis energy chain such as the triflex® R from igus® makes it possible to guide robot cables safely. In order to recognise potential chain breakages caused by the extreme load in good time and avoid unplanned machine downtime, igus has developed i.Sense TR.B, the world's first breakage monitoring system for multi-axis energy chains.

Extremely light, but always in the picture ...

... the new i.Sense igubal® sensor

The intelligent flange mounted bearing from smart plastics permanently monitors the condition of the bearing point and immediately reports the first signs of wear in order to prevent serious bearing damage. The aim is to receive an immediate message if the bearing properties deteriorate. This prevents expensive malfunctions and failures.

Direct real-time monitoring easier than ever ...

... with the new smart plastics MWS

The smart plastics miniature wear sensor (MWS) is used to detect the percentage of abrasion on moving system parts in order to prevent possible operational failures at an early stage.

Now also with visual status display ...

Detect cable stress at an early stage with i.Sense CF.D

Until now, there have often only been two options for servicing and maintaining mechanically stressed cables: either they are only replaced reactively when they are already defective or cables that are still functional are replaced at certain intervals as a precaution.

The new i.Sense CF.D module from smart plastics is the first real alternative to this: the predictive maintenance of data, bus or Ethernet cables by means of intelligent monitoring of data transmission quality during operation.

Complete monitoring of all bearing positions ...

... with the new i.Sense BRG mini sensor

With the new mini sensor i.Sense BRG you have a complete view of all bearing positions. Because with this new product you can make (virtually) every plastic product from igus "smart"; i.e. as a user you benefit from real-time condition monitoring including digital evaluation options for the recorded machine data. In combination with the i.Cee module, predictive maintenance recommendations and service life statements are then issued.

Small but mighty: smart plastics DIY tools

The easiest way to enter the world of sensor technology

Modern industry would be unthinkable without sensors as data sources. With smart plastics, we have been consistently moving in this direction for almost 10 years, developing new, intelligent monitoring systems for energy supply systems, cables and linear guide every year. Now we want to make this accessible to even more users and are entering the world of low-cost sensor technology with our smart plastics DIY tools.

Intuitive tension monitoring for AG5

Cable tension indicator as a smart sensor option

Safe energy supply over long distances at a cost-effective price - that is the autoglide 5. The energy chain system autoglide 5 is specially designed for horizontal use in material handling and on crane systems. The energy supply is quick to install as it does not have a guide trough. Instead, it rests on a tensioned cable using a special underside construction. And that is exactly what this new product, the AG5 smart sensor option, is all about.

Extending service life made easy ...

... with the EC.W wear sensor in the e-chain online configurator

A quick and easy way to a customised solution: with the help of the "e-chain expert", interested parties can put together a customised energy chain system in just three steps. Including transparent display of price, service life and delivery time. For the first time, users now have the option of configuring their e-chain directly with the intelligent i.Sense EC.W wear sensor. This provides customers with a complex, ready-to-connect e-chain system including real-time condition monitoring - and all with just a few clicks.

Lean, green ... and smart

Smart technology as standard in many e-chain® News

Digitalisation on all (travel) paths: whether in the cleanroom, in the theatre or in rotary movements ... the demand for intelligent condition monitoring, and therefore increased safety and a longer service life, is becoming ever stronger. This is why there are once again many new energy supply highlights this year, which are already equipped with the proven smart plastics technology for intelligent condition monitoring and predictive maintenance as standard.

Our new products from

News 2022

Energy supply made smart - through new products and sustainability

Our task is to constantly develop new products for e-chains and cables. In this way, we enable you to simultaneously save costs and further increase the quality of machines and systems, i.e. "Tech up. Cost down".

We at igus also take our responsibility of reducing plastic waste and improving recycling seriously: when drag or energy chains reach the end of their service life, we have them processed in the igus recycling program. Find out more about our investment in Chemical Recycling of Mura Technology Limited.

IMPS - igus motion plastics show

A 400m² physical-virtual trade show stand that you can visit whenever you like.

You can explore the trade show stand on your own or together with one of our experts:

NEW for PLC with visual status display ...

... Detect cable stress at an early stage with i.Sense CF.D

Until now, there have often only been two options for servicing and maintaining mechanically stressed cables: either they are only replaced reactively when they are already defective or cables that are still functional are replaced at certain intervals as a precaution.

The new i.Sense CF.D module from smart plastics is the first real alternative to this: the predictive maintenance of data, bus or Ethernet cables by means of intelligent monitoring of data transmission quality during operation.

More service life has never been so cost-effective ...

... with the new i.Sense EC.W service life sensor

The new i.Sense EC.W sensor makes more system availability more cost-effective than ever before. Thanks to the direct connection to the PLC machine control system via potential-free contacts, real-time status monitoring for your sliding energy supply systems is possible from just EUR 248.00 (DE list).

This makes it easier than ever to avoid unplanned downtimes and increase system availability.

Finally also for multi-axis & industrial robots ...

... i.Sense TR.B for intelligent condition monitoring

Robots have long been an integral part of many areas of industrial production - whether welding, painting, soldering or palletising: industrial robots work dynamically. A flexible multi-axis energy chain such as the triflex® R from igus® makes it possible to guide robot cables safely. In order to recognise potential chain breakages caused by the extreme load in good time and avoid unplanned machine downtime, igus has developed i.Sense TR.B, the world's first breakage monitoring system for multi-axis energy chains.

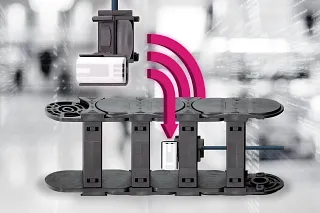

First contactless system monitoring ...

... thanks to the new i.Cee wonderbox

With contactless system monitoring for sliding e-chain systems® (with & without rollers), igus® has achieved a technological sensation. The new i.Cee wonderbox measures the dynamic parameters of the "passing" chain without contact, similar to a speed trap on the motorway. By comparing standard values from years of experience in the igus test laboratory, changes in condition can be recognised at an early stage and precise service life predictions can be made for each individual chain link.

"Pure" world premiere ...

... Predictive maintenance in the cleanroom with i.Cee EC.S

The smart ultrasonic sensor technology in this cleanroom highlight is used to continuously monitor the current sag of the support chain. The e-skin® flat with support chain SKF.S is equipped with a defined bend radius and therefore also enables free-running lengths in the cleanroom. As soon as a critical condition of the energy supply system is detected, predictive maintenance recommendations are issued.

Reliable energy supply ...

... without a big theatre thanks to i.Sense ES.B

The new theatre e-spool now comes with various smart features: The spring force of the three springs contained is monitored using a load cell sensor. If the force falls below this level, the user is notified to replace the spring. If the force is exceeded, there is a blockage that must be removed.

A rotation sensor monitor can also be installed, which counts the drum revolutions and determines the position of the chain. As further protection to increase system safety, the tried and tested i.Sense EC.P for push/pull force monitoring could also be installed at the moving end of the chain in the future.

All-in-one: New customer portal i.Cee:portal ...

... for all smart plastics components

In the new i.Cee:portal, numerous functions and use cases will be made available centrally in a single location in future:

- Secure (VPN), authenticated access to local i.Cee dashboards

- Overview of all customer assets (online and offline)

- Remote configuration & reset of individual assets

- Status report of all assets

- Alarm & message overview

Prevent unplanned downtimes with three clicks ...

... in the new i.Sense online shop

Following on from the smart plastics complete set, the i.Sense EC.P systems for push/pull force monitoring and i.Sense EC.B for breakage detection can now also be fully configured with display of prices and ordered directly in the i.Sense online shop.

The individual system configuration depending on the application can be easily selected using several selection criteria (chain series, length, switch cabinet position, excess cable length). The appropriate parts list, price and delivery time are then issued accordingly. Further information such as EPLAN macros and operating and assembly instructions can also be viewed directly in the shop.

Intelligent system monitoring ...

... in the Smart Factory from FANUC & igus

To analyse data from machines and systems directly on site, the international robot manufacturer Fanuc offers its open industrial IoT platform "FIELD system". The system can connect production machines from all manufacturers via a local network topology, enabling comprehensive data analysis of the entire process chain.

Both Fanuc and third-party apps are used in this infrastructure. With the igus app "smart plastics - i.Cee", maintenance technicians can monitor the condition of their igus components in the FIELD system at any time and plan maintenance in advance.

Draw electrical plans faster ...

... with the new smart plastics EPLAN macros

EPLAN Electric P8, one of the main products of EPLAN GmbH & Co. KG, is regarded as one of the industry standards for electrical design and supports plant project planning from end-to-end planning up to production, commissioning, servicing and maintenance.

Based on various studies, it has been determined that it is possible to optimise the time required to design a typical switch cabinet, including all control modules, by over 50%.

Digitalisation on all (travel) paths ...

... with many more smart chain highlights in 2022

- The modular extension E4.80R now comes with the full i.Sense product range for intelligent condition monitoring EC.B, EC.P and CF.P.

- The new hybrid chain YE(HD) can now also be protected against unexpected downtimes with the smart breakage detection i.Sense EC.B.

- In the new AG5.RAIL design study, i.Sense EC.P and EC.W directly lay the foundation for a predictive maintenance concept.

- As an option, the e-dispenser also offers smart plastics rotation monitoring.

"Intelligent rebel of automation" ...

... smart plastics now also in the igus cobot ReBeL®

For the latest generation of service robots with cobot function, igus has also incorporated its motion plastics expertise into the power electronics and developed an encoder using conductive plastic tracks for the first time. This allows the number of rotations and cycles, passes, temperature and current to be measured precisely.

Thanks to the connection via the smart plastics systems, a dashboard clearly displays all generated data live - either via the cloud or in the local network, depending on the customer's requirements. This gives the customer full transparency about their smart ReBeL® in operation, about key figures such as wear, cycle time and quantities.

Complete monitoring of all bearing positions ...

... with the new i.Sense BRG mini sensor

With the new i.Senser BRG mini sensor, you have complete monitoring of all bearing position(s). Because with this new product you can make (almost) every plastic product from igus "smart"; i.e. as a user you benefit from real-time condition monitoring including digital evaluation options for the recorded machine data. In combination with the i.Cee module, predictive maintenance recommendations and service life statements are then issued.